產品說明

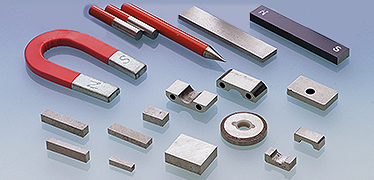

釹鐵硼超強力磁鐵是目前市面上所有磁鐵材質中磁力最強的磁石。

釹鐵硼超強力磁鐵的製造方式是粉末成型後,經燒結加工而成。因為釹鐵硼超強力磁鐵具有超強的磁力,所以廣泛應用於輕薄短小的產品。一般說來,釹鐵硼磁石為了防止表面氧化,其表面常鍍鎳、鍍鋅或環氧樹脂等處理,但即使表面作了防鏽處理,經過一段時間後(視擺放環境,約一年左右),仍會有表面氧化現象發生。

雖然表面有了氧化現象,但對磁石本身的磁力強度無任何影響,亦無影響性能。除此之外,使用上需注意一種材質等級所能耐受的溫度係數,釹鐵硼超強力磁鐵雖然磁力超強,但溫度係數要較鋁鎳鈷合金磁石等來的低。

應用範圍:

釹鐵硼超強力磁鐵具有超強磁力、表面電鍍處理、尺寸不拘、免模費等特性及優點。

各種需超強磁力或需較小體積及輕量需求的產品均可應用之,如手機元件、DC直流強力無刷馬達、磁性工具、磁盤、輸送機械元件、磁力煞車、幫浦、無桿汽缸、強力發電機、揚聲器、鐘錶元件、磁化水裝置、省油裝置、磁性治療、滾輪、濺鍍設備元件、吊重工具、自動元件、磁浮元件、消磁器、磁簧感應元件、超強力磁棒等。

釹鐵硼超強力磁鐵具有超強磁力、表面電鍍處理、尺寸不拘、免模費等特性及優點。

各種需超強磁力或需較小體積及輕量需求的產品均可應用之,如手機元件、DC直流強力無刷馬達、磁性工具、磁盤、輸送機械元件、磁力煞車、幫浦、無桿汽缸、強力發電機、揚聲器、鐘錶元件、磁化水裝置、省油裝置、磁性治療、滾輪、濺鍍設備元件、吊重工具、自動元件、磁浮元件、消磁器、磁簧感應元件、超強力磁棒等。

性能表

|

燒結釹鐵硼磁鐵性能參數表 Sintered NdFeb magnet performance parameter table |

|||||||||||||||

| 類別 | 性能 | 剩磁 Remanence Br | 矯頑力 Coercivty bHc | 内禀矯頑力

Intrinsic Coercivty iHc |

最 大 磁 能 積

Max Energy Product(BH)max |

方形度% Square degree% | 工作温度°C

Working Temperature |

||||||||

| KGs | T | KOe | KA/m | KOe | KA/m | MGOe | KJ/㎥ | Hk/Hcj | When PC=2 | ||||||

| Min. | Max. | Min. | Max. | Min. | Min. | Min. | Min. | Min. | Min. | Min. | Max | Min. | Typical | ||

| ND | ND35 | 11.8 | 12.3 | 1.18 | 1.23 | 10.5 | 836 | 11 | 876 | 33 | 36 | 263 | 287 | 95 | 80 |

| ND38 | 12.3 | 12.6 | 1.23 | 1.26 | 10.5 | 836 | 11 | 876 | 36 | 39 | 287 | 310 | 95 | 80 | |

| ND40 | 12.6 | 12.9 | 1.26 | 1.29 | 10.5 | 836 | 11 | 876 | 38 | 41 | 302 | 326 | 95 | 80 | |

| ND42 | 12.9 | 13.3 | 1.29 | 1.33 | 10.5 | 836 | 11 | 954 | 40 | 43 | 318 | 342 | 95 | 80 | |

| ND45 | 13.3 | 13.7 | 1.33 | 1.37 | 10.5 | 836 | 11 | 876 | 43 | 46 | 342 | 366 | 95 | 80 | |

| ND48 | 13.7 | 14.1 | 1.37 | 1.41 | 10.5 | 836 | 11 | 876 | 45 | 49 | 358 | 390 | 95 | 80 | |

| ND50 | 14 | 14.4 | 1.4 | 1.44 | 10.5 | 836 | 11 | 876 | 47 | 51 | 374 | 406 | 95 | 80 | |

| ND52 | 14.3 | 14.8 | 1.43 | 1.48 | 10.5 | 836 | 11 | 876 | 49 | 53 | 390 | 422 | 95 | 80 | |

| ND54 | 14.7 | 15 | 1.47 | 1.5 | 10.5 | 836 | 11 | 876 | 51 | 55 | 406 | 438 | 95 | 80 | |

| M | ND35M | 11.8 | 12.3 | 1.18 | 1.23 | 11.2 | 892 | 14 | 1114 | 33 | 36 | 263 | 287 | 95 | 100 |

| ND38M | 12.3 | 12.6 | 1.23 | 1.26 | 11.5 | 915 | 14 | 1114 | 36 | 39 | 287 | 310 | 95 | 100 | |

| ND40M | 12.6 | 12.9 | 1.26 | 1.29 | 11.8 | 939 | 14 | 1114 | 38 | 41 | 302 | 326 | 95 | 100 | |

| ND42M | 12.9 | 13.3 | 1.29 | 1.33 | 12 | 955 | 14 | 1114 | 40 | 43 | 318 | 342 | 95 | 100 | |

| ND45M | 13.3 | 13.7 | 1.33 | 1.37 | 12.2 | 971 | 14 | 1114 | 43 | 46 | 342 | 366 | 95 | 100 | |

| ND48M | 13.7 | 14.1 | 1.37 | 1.41 | 12.7 | 1011 | 14 | 1114 | 45 | 49 | 358 | 390 | 95 | 100 | |

| ND50M | 14 | 14.4 | 1.4 | 1.44 | 13 | 1035 | 14 | 1114 | 47 | 51 | 374 | 406 | 95 | 100 | |

| ND52M | 14.3 | 14.8 | 1.43 | 1.48 | 12.8 | 1019 | 14 | 1114 | 49 | 53 | 390 | 422 | 95 | 100 | |

| H | ND33H | 11.4 | 11.8 | 1.14 | 1.18 | 10.8 | 860 | 17 | 1353 | 31 | 34 | 247 | 271 | 95 | 120 |

| ND35H | 11.8 | 12.3 | 1.18 | 1.23 | 11 | 876 | 17 | 1353 | 33 | 36 | 263 | 287 | 95 | 120 | |

| ND38H | 12.3 | 12.6 | 1.23 | 1.26 | 11.5 | 915 | 17 | 1353 | 36 | 39 | 287 | 310 | 95 | 120 | |

| ND40H | 12.6 | 12.9 | 1.26 | 1.29 | 11.8 | 939 | 17 | 1353 | 38 | 41 | 302 | 326 | 95 | 120 | |

| ND42H | 12.9 | 13.3 | 1.29 | 1.33 | 12.5 | 995 | 17 | 1353 | 40 | 43 | 318 | 342 | 95 | 120 | |

| ND45H | 13.3 | 13.7 | 1.33 | 1.37 | 12.7 | 1011 | 17 | 1353 | 43 | 46 | 342 | 366 | 95 | 120 | |

| ND48H | 13.7 | 14.1 | 1.37 | 1.41 | 12.8 | 1019 | 17 | 1353 | 45 | 49 | 358 | 390 | 95 | 120 | |

| ND50H | 14 | 14.4 | 1.4 | 1.44 | 13 | 1035 | 16 | 1273 | 47 | 51 | 374 | 406 | 95 | 120 | |

| SH | ND30SH | 10.9 | 11.4 | 1.09 | 1.14 | 10.3 | 820 | 20 | 1592 | 28 | 31 | 223 | 247 | 90 | 150 |

| ND33SH | 11.4 | 11.8 | 1.14 | 1.18 | 10.8 | 860 | 20 | 1592 | 31 | 34 | 247 | 271 | 90 | 150 | |

| ND35SH | 11.8 | 12.3 | 1.18 | 1.23 | 11 | 876 | 20 | 1592 | 33 | 36 | 263 | 287 | 90 | 150 | |

| ND38SH | 12.3 | 12.6 | 1.23 | 1.26 | 11.5 | 915 | 20 | 1592 | 36 | 39 | 287 | 310 | 90 | 150 | |

| ND40SH | 12.6 | 12.9 | 1.26 | 1.29 | 11.8 | 939 | 20 | 1592 | 38 | 41 | 302 | 326 | 90 | 150 | |

| ND42SH | 12.9 | 13.3 | 1.29 | 1.33 | 12.5 | 995 | 20 | 1592 | 40 | 43 | 318 | 342 | 90 | 150 | |

| ND45SH | 13.3 | 13.7 | 1.33 | 1.37 | 12.7 | 1011 | 20 | 1592 | 43 | 46 | 342 | 366 | 90 | 150 | |

| ND48SH | 13.7 | 14.1 | 1.37 | 1.41 | 12.8 | 1019 | 19 | 1512 | 45 | 49 | 358 | 390 | 90 | 150 | |

| ND50SH | 13.9 | 14.3 | 1.39 | 1.43 | 13 | 1035 | 19 | 1512 | 47 | 51 | 374 | 406 | 90 | 150 | |

| UH | ND30UH | 10.9 | 11.4 | 1.09 | 1.14 | 10.2 | 812 | 25 | 1990 | 28 | 31 | 223 | 247 | 90 | 180 |

| ND33UH | 11.4 | 11.8 | 1.14 | 1.18 | 10.8 | 860 | 25 | 1990 | 31 | 34 | 247 | 271 | 90 | 180 | |

| ND35UH | 11.8 | 12.3 | 1.18 | 1.23 | 11.2 | 896 | 25 | 1990 | 33 | 36 | 263 | 287 | 90 | 180 | |

| ND38UH | 12.3 | 12.6 | 1.23 | 1.26 | 11.6 | 923 | 25 | 1990 | 36 | 39 | 287 | 310 | 90 | 180 | |

| ND40UH | 12.6 | 12.9 | 1.26 | 1.29 | 12 | 955 | 25 | 1990 | 38 | 41 | 302 | 326 | 90 | 180 | |

| ND42UH | 12.9 | 13.3 | 1.29 | 1.33 | 12.2 | 971 | 25 | 1990 | 40 | 43 | 318 | 342 | 90 | 180 | |

| ND45UH | 13.3 | 13.6 | 1.33 | 1.36 | 12.3 | 979 | 24 | 1990 | 43 | 46 | 342 | 366 | 90 | 180 | |

| ND48UH | 13.7 | 14.1 | 1.37 | 1.41 | 12.8 | 1019 | 24 | 1910 | 45 | 49 | 358 | 390 | 90 | 180 | |

| ND50UH | 13.9 | 14.3 | 1.39 | 1.43 | 13 | 1035 | 24 | 1910 | 47 | 51 | 374 | 406 | 90 | 180 | |

| EH | ND30EH | 10.9 | 11.4 | 1.09 | 1.14 | 10.3 | 820 | 30 | 2388 | 28 | 31 | 223 | 247 | 90 | 200 |

| ND33EH | 11.4 | 11.8 | 1.14 | 1.18 | 10.8 | 860 | 30 | 2388 | 31 | 34 | 247 | 271 | 90 | 200 | |

| ND35EH | 11.8 | 12.2 | 1.18 | 1.22 | 11.1 | 884 | 30 | 2388 | 33 | 36 | 263 | 287 | 90 | 200 | |

| ND38EH | 12.2 | 12.6 | 1.22 | 1.26 | 11.3 | 923 | 30 | 2388 | 36 | 39 | 287 | 310 | 90 | 200 | |

| ND40EH | 12.5 | 12.9 | 1.25 | 1.29 | 11.9 | 947 | 30 | 2388 | 38 | 41 | 302 | 326 | 90 | 200 | |

| ND42EH | 12.8 | 13.3 | 1.28 | 1.33 | 12.2 | 971 | 29 | 2308 | 38 | 43 | 310 | 3442 | 90 | 200 | |

| ND28AH | 10.5 | 11 | 1.05 | 1.1 | 9.8 | 780 | 35 | 2786 | 26 | 29 | 207 | 231 | 90 | 220 |

| AH | ND30AH | 10.8 | 11.4 | 1.09 | 1.14 | 10.1 | 804 | 35 | 2786 | 28 | 31 | 223 | 247 | 90 | 220 |

| ND33AH | 11.4 | 11.8 | 1.14 | 1.18 | 10.2 | 812 | 335 | 2786 | 31 | 34 | 247 | 271 | 90 | 220 | |

| ND35AH | 11.8 | 12.2 | 1.18 | 1.22 | 10.6 | 844 | 35 | 2786 | 33 | 36 | 263 | 287 | 90 | 220 | |

| ND38AH | 12.2 | 12.6 | 1.22 | 1.26 | 11.6 | 923 | 33 | 2627 | 35 | 29 | 279 | 310 | 90 | 220 | |

| NdFeB T-Series Magnetic Properties: | |||||||||||||||

| SH-T | ND35SH-T | 11.8 | 12.3 | 1.18 | 1.23 | 11 | 884 | 23 | 1592 | 33 | 36 | 263 | 287 | 90 | 160 |

| ND38SH-T | 12.3 | 12.6 | 1.23 | 1.26 | 11.6 | 923 | 23 | 1592 | 36 | 39 | 287 | 310 | 90 | 160 | |

| ND40SH-T | 12.6 | 12.9 | 1.26 | 1.29 | 12 | 955 | 23 | 1592 | 38 | 41 | 302 | 326 | 90 | 160 | |

| ND42SH-T | 12.9 | 13.3 | 1.29 | 1.33 | 12 | 955 | 23 | 1592 | 40 | 43 | 318 | 342 | 90 | 160 | |

| ND45SH-T | 13.3 | 13.7 | 1.33 | 1.37 | 12.4 | 987 | 23 | 1592 | 43 | 46 | 342 | 366 | 90 | 160 | |

| ND48SHH | 13.7 | 14.1 | 1.3 | 1.41 | 12.8 | 1019 | 20 | 1512 | 45 | 49 | 358 | 390 | 90 | 160 | |

| ND50SH-T | 13.9 | 14.3 | 1.39 | 1.43 | 13 | 1035 | 20 | 1512 | 47 | 51 | 374 | 406 | 90 | 160 | |

| UH-T | ND30UH- | 10.9 | 11.4 | 1.09 | 1.14 | 10.2 | 812 | 25 | 1990 | 28 | 31 | 223 | 247 | 90 | 190 |

| ND33UH- | 11.4 | 11.8 | 1.14 | 1.18 | 10.8 | 860 | 25 | 1990 | 31 | 34 | 247 | 271 | 90 | 190 | |

| ND35UH- | 11.8 | 12.3 | 1.18 | 1.23 | 11.2 | 896 | 25 | 1990 | 33 | 36 | 263 | 287 | 90 | 190 | |

| ND38UH- | 12.3 | 12.6 | 1.23 | 1.26 | 11.6 | 923 | 25 | 1990 | 36 | 39 | 287 | 310 | 90 | 190 | |

| ND40UH- | 12.6 | 12.9 | 1.26 | 1.29 | 12 | 955 | 25 | 1990 | 38 | 41 | 302 | 326 | 90 | 190 | |

| ND42UH- | 12.9 | 13.3 | 1.29 | 1.33 | 12.2 | 971 | 25 | 1990 | 40 | 43 | 318 | 342 | 90 | 190 | |

| ND45UH- | 13.3 | 13.6 | 1.33 | 1.36 | 12.3 | 979 | 24 | 1990 | 43 | 46 | 342 | 166 | 90 | 190 | |

| Remark;For other grades and custom-made grades,please contact our sales departnent. Actual working temperature is related to pc.

備註:其他要求的定制特殊性能,請跟我們的業務聯繫;產品實際工作溫度和Pc值相關 |

|||||||||||||||

| 燒結釹鐵硼規格參數選型表,常用的釹鐵硼規格大全牌號性能大全,接受定制

Sintered ndFeb specification parameter selection table, commonly used NdFeb specification complete brand performance complete, accept customization |

|||||||||||||||

製作流程

-

原料

-

熔鍊

-

鑄錠

-

(粗、細)粉碎

-

真空超細粉碎

Jet Mill-

異方性磁場配向

-

垂直壓

-

冷均壓

-

燒結及熱處理

-

切割、研磨加工

-

表面處理

-

成品(著磁)

-

-

-

-

-

平行壓

-

-

-

-

-

-